CONTACT IN HANOI

CONTACT IN HANOI

Hotline : 0961230808 exit 1

Email : giangthanh@maymaygiangthanh.com

CONTACT IN HCM

CONTACT IN HCM

Hotline : 0961230808 exit 3

Email : hcm@maymaygiangthanh.com

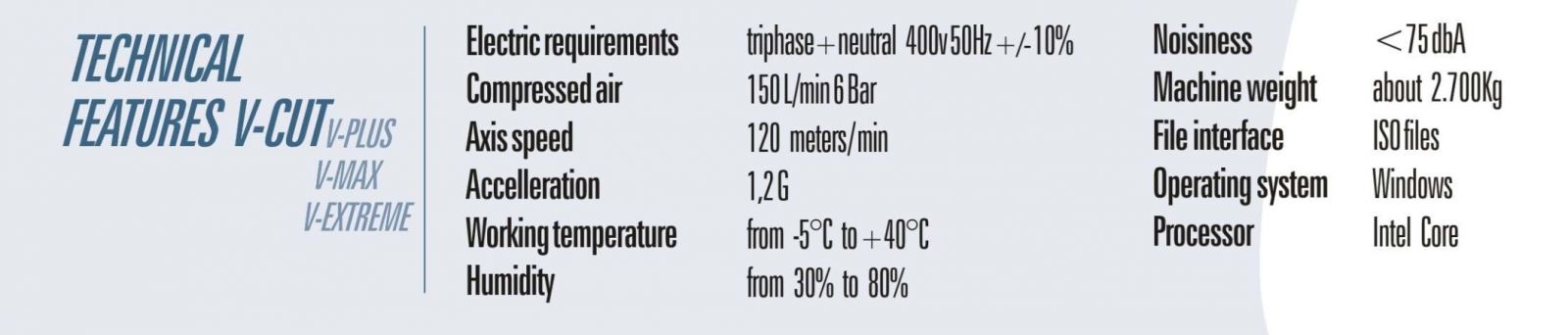

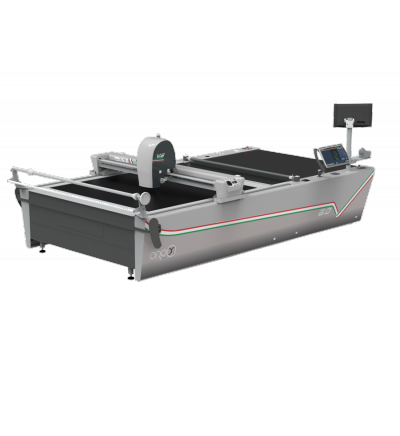

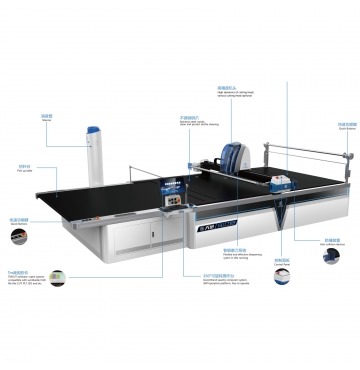

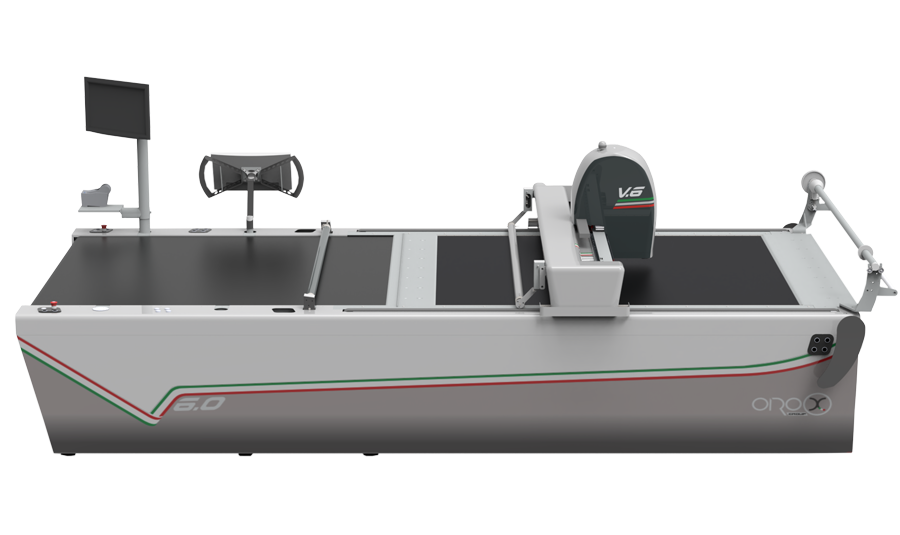

The Orox V8 automatic cutting machine is a high-end cutting machine with Italian origin, capable of cutting various types of fabrics such as Silk, Cotton, synthetic fabrics, etc., for applications like Knit & Jeans, with a cutting thickness of 8 CM after compression.

The Orox industrial cutting machine is one of the most versatile and advanced cutting machines available today, produced with the latest hardware and software technologies in Italy.

The Orox industrial cutting machine can cut various layers of fabric from 1 layer to multiple layers with a cutting thickness of up to 8 cm, at a cutting speed of 120 meters/minute. It is specialized for textile industries, furniture manufacturing, automotive, and cutting various industrial fabrics. Utilizing the Cosma cutting machine will help businesses save fabric, achieve high precision, save time with higher cutting efficiency, improve product quality, and enhance competitiveness in the Industry 4.0 era.

Advantages of the Orox Industrial Cutting Machine

- Specialized in cutting various materials

- High cutting speed of 120m/minute

- Cutting thickness after compression is 8 cm

- Intelligent cutting software with automatic recognition of start points, curves, straight lines, angles, cutting edges, drilling, and precise cutting adjustments to suit high-quality standards.

- Precision cutting without the need for spacing between closely nested details, saving fabric up to 1-3%

- Utilizes an intelligent moving and cutting system (SMS) for simultaneous movement and cutting without stopping, saving cutting time and increasing production efficiency by 1-2%.

- Precision automatic adjustment system for cutting on straight paths at high speed and reducing speed on curved paths.

- Uses dual foot pedal with 2 inverter technologies, allowing the machine to reach up to 200mb vacuum power for stronger fabric hold and achieving high cutting precision and layer alignment. The inverter technology controls the vacuum power for cutting fabrics of varying thicknesses from thin to thick without the need for manual adjustments.

- Utilizes linear motion guide for precise and smooth machine operation.

- Smart blade system: adjusts blade angle during high layer cutting, ensuring no deflection, no edge damage, and maintains normal blade temperature during cutting to avoid fabric burning due to heat.

- Durable blade life, cost-effective, adjustable blade angle for desired results, ensuring high blade durability and consistent cutting quality. Each blade edge can last more than 1 year.

- Table brush design ensures high adhesion, 5x5cm size for fabric layer alignment.

- Energy-saving: dual operation of vacuum feet adjusts according to fabric layer height, reducing power consumption.

- Automated maintenance alerts for daily, weekly, monthly machine checks, blade replacement reminders.

- Low maintenance costs: minimal part replacements and consumption.

- Equipped with the latest electrical and software components for remote support, repair, and software updates.

- Uses Parker USA PNC control system for faster operation and easy upgrades.

- Complies with ISO, CUT standards, compatible with various design software.

Benefits of Using the Orox Industrial Cutting Machine

- Reduces fabric cutting time

The Cosma cutting machine has a cutting speed of 120 meters per minute, speeding up the fabric cutting process. With modern technology, sensor systems, intelligent movement, and cutting (SMS), the cutting process is fully automated, highly precise, ensuring smooth fabric layers, high quality, and alignment between layers.

- Saves labor costs

Orox cutting machines are user-friendly and fully automated, requiring minimal manual labor for cutting operations and material handling.

- Improves product quality

The Orox industrial cutting machine uses various sensors for high-precision cutting control. The smart blade system reduces cutting errors, ensuring smooth cut edges. This enhances product quality significantly.

- Saves material costs

The Cosma cutting machine can cut fabrics closely nested without gaps, optimizing fabric usage and reducing waste.

- Cost-effective, increased production efficiency

The Orox industrial cutting machine saves energy, reduces maintenance costs, and part replacements. It provides real-time data connection for easy management and production planning, enhancing workforce productivity and operational efficiency.