Automatic Fiber Filling and Down Filling Machine Bealead DF-4606X

Contact

Product code : DF-4606X

Views : 799

CONTACT IN HANOI

CONTACT IN HANOI

Hotline : 0961230808 exit 1

Email : giangthanh@maymaygiangthanh.com

CONTACT IN HCM

CONTACT IN HCM

Hotline : 0961230808 exit 3

Email : hcm@maymaygiangthanh.com

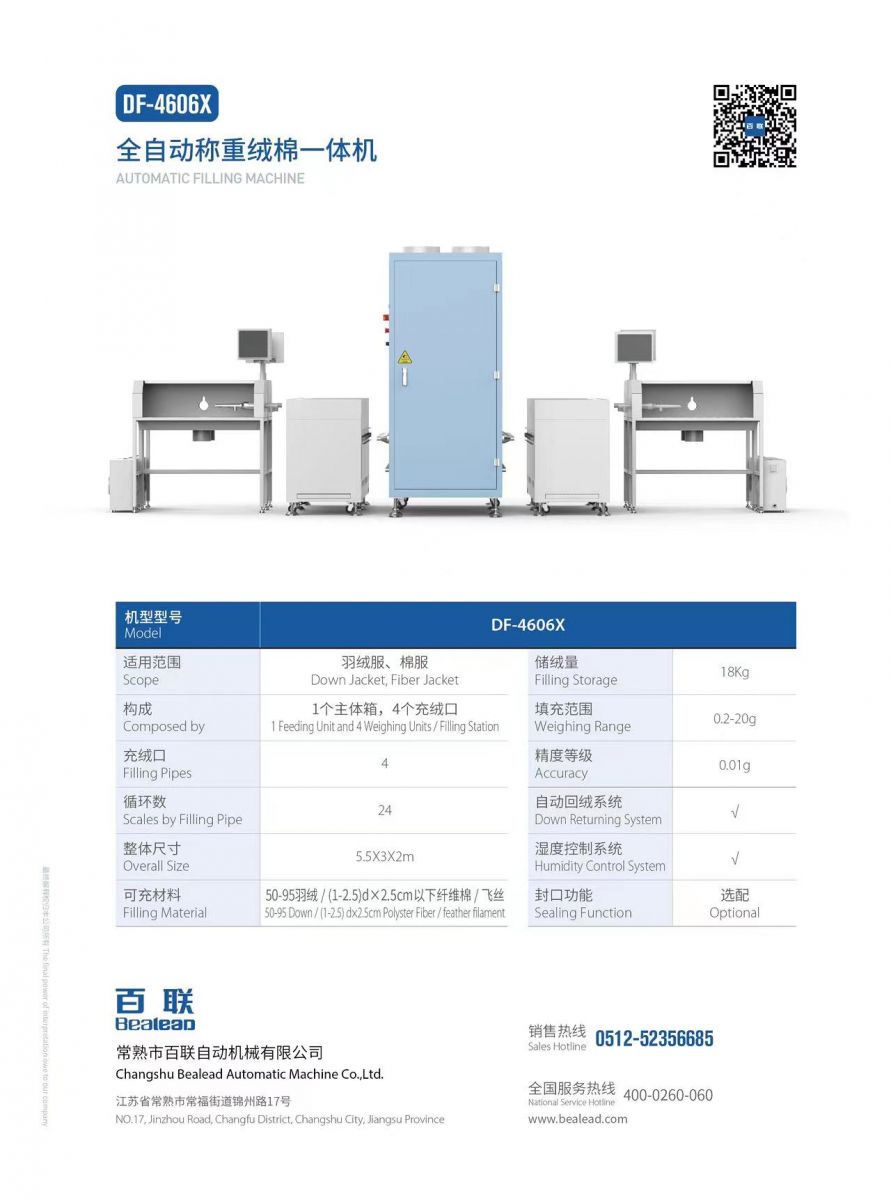

Automatic Fiber Filling Machine DF-4606X is a 4-head machine with 24 scales, which stuffs fiber faster than manual work with 1 head, helping businesses increase productivity and reduce product costs.

The machine integrates all parts into one block, saving more space.

The machine uses a vacuum weighing system to ensure absolute accuracy.

The fiber filling range per fabric compartment is 0.1-15.0g, suitable for both large and small fabric compartments.

Simple computer operation, data storage, time control, and data modification.

WORKING PRINCIPLE

Based on a high-pressure air system to stuff fiber, the machine determines the amount of fiber to be filled automatically by time, then adjusts the amount of fiber accurately to proceed with automatic filling.

TECHNICAL INFORMATION

Model: DX-4405F

Fiber filling doors: 4

Fiber filling machine speed: 3,000 - 6,000 products/hour

Filling capacity: About 10 kg (Fiber)

Fiber requirement: 90/10, 80/20, 60/40 dry fiber.

Machine tolerance: +-2% (tested in standard environment with 90 fiber)

Origin: China

PRESSURE REQUIREMENTS:

Minimum supply pressure required: 0.8m3/minute or higher.

Air compressor power from 7.5kw or higher (ensuring sufficient air supply)

Recommended pressure level: 1.0Mpa, minimum pressure: 0.58Mpa.

Air storage tank volume from 0.6m3 or higher, stabilizing pressure level, extending the air compressor lifespan.

ENVIRONMENTAL REQUIREMENTS (SUGGESTED):

Temperature: According to GTB 14272-2011 standard requirements, suitable temperature during fiber filling is around 20 degrees (+-2).

Humidity: According to GTB 14272-2011 standard requirements, suitable humidity during fiber filling is around 65% (+-4)